Description

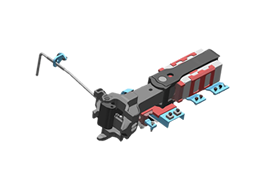

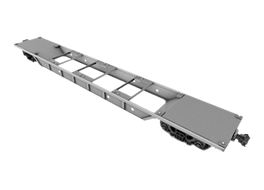

A twist lock and corner casting together form a standardized rotating connector for securing shipping containers. The primary uses are for locking a container into place on container ship, semi-trailer truck or railway container train; and for lifting of the containers by container cranes and side lifters.

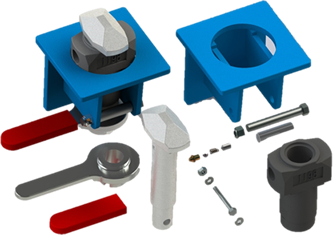

According to the operation modes,Twist lock can be divided into three types :Manual type,semi-automatic type,automatic type.

Twislock type sheet

| Type | Automatic twistlock | Semi Automatic Twistlock | Manual Twist Lock | |||||||

| Holland type | Normal | Large Base | Rail Interbox Connectors | Normal | Fixed Base | Breech Base | Dovetail | Truck Chassis Flat Bed | Rail Interbox Connectors | |

|  |  |  |  |  |  |  |  |  | |

| Except | Our products cover | |||||||||

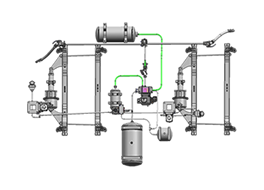

Mechanism

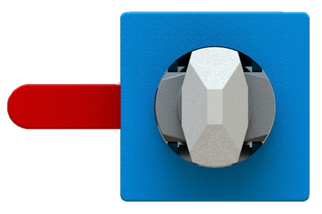

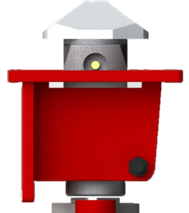

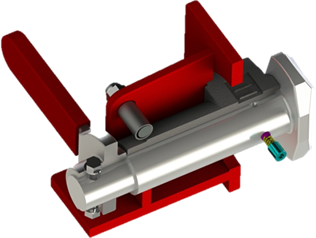

The female part of the connector is the 7×7×4 1⁄2 in (180×180×110 mm) corner casting, which is fitted to the container itself, and has no moving parts, only an oval hole in the bottom. The hole is an oval 4.9 in (124.5 mm) on the long axis with two flat sides 2.5 in (63.5 mm) apart. The male component is the twist lock, which is fitted to cranes and transport bases. This can be inserted through the hole (it is roughly 4.1 in or 104.1 mm long and 2.2 in or 55.9 mm wide), and then the top portion (normally pointed to make insertion easier) is rotated 90° so that it cannot be withdrawn. The mechanism is similar to that of a Kensington lock, but on a much larger scale. The maximum size and position of the holes in the connector is defined in international standard ISO 1161. The tensile strength of a twist lock is rated at either 20 or 25 tonnes.

Specification

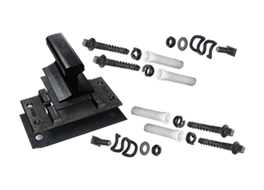

Tedrail can supply the manual twist lock(Series TRM198) and semi-automatic twislock,we also can develop the automatic twist lock.

Designed to fit ISO Corner castings

Cast steel housing and forged steel pin

Meets all AAR M-952 requirements

Can be deck mounted with no cutting

Easy weld application

High quality manufacturing and testing