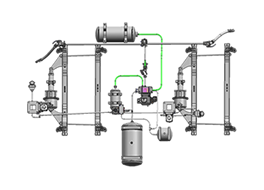

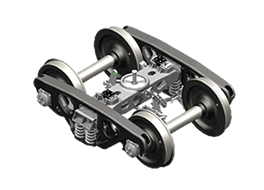

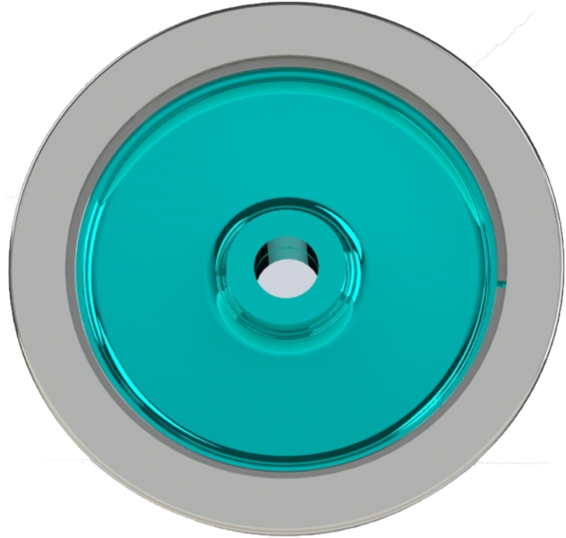

Tyred wheel, also called tired wheel is a combined rail wheel, which is composed of wheel tyre, Wheel Center, Gibson Ring. The utilization of traditional freight wagons was often so low that tires never needed renewal, so it was cheaper to fit a one-piece ("monoblock") wheel.

Replacing a whole wheel because of a worn contact surface was expensive, so older types of railway wheels were fitted with a replaceable steel tire. The tire is a hoop of steel that is fitted around the steel wheel center. Regularly tyred wheels are used on application of locomotive and some freight wagon.

As a result, Tyred wheel should be assembled according to special process by wheel center, wheel tyre, and Gibson ring according to following specifications:

EUROPEAN STANDARD, BS 5892-6 Railway rolling stock materials. Specification for wheelsets for traction and trailing stock

CHINESE RAILWAY STANDARD, TB/T 1718 Technical requirements of railway vehicle’s wheelset installation.

The tire is machined with a shoulder on its outer face to locate it on the wheel centre, and a groove on the inside diameter of the flange face. The inside diameter of the tire is machined to be slightly less than the diameter of the wheel centre on which it is mounted, to give an interference fit.

The tire is fitted by heating to a controlled temperature, avoiding overheating. This causes the tire to expand. The wheel centre, usually already mounted on the axle, is lowered into the tire which is flange side up. The tire cools, and the gibson ring (a shaped steel bar rolled into a hoop) is fitted into the groove. Hydraulically operated rolls swage the groove down on to the gibson ring.

RAILWAY WHEEL CENTRE

Railway Wheel center has been pressed together with wheel tyre and Gibson ring to be tyred wheel. The hub is assembled with railway axle, and functioned as wheelset. According to different specification, the wheel centre can be manufactured by

Casting

Forged or Rolled

MANUFACTURING SPECIFICATIONS:

FORGED, ROLLED WHEEL CENTRE

From European standard, the wheel center has to be forged and rolled. TEDRAIL can deliver the forged wheel centre as following related specifications:

BRITISH STANDARD: BS 5892 PART 2, Railway rolling stock materials –Part 2. Specification for forged and rolled wheel centres

EUROPEAN STANDARD: UIC 812-1Technical specification for the supply of forged or rolled wheel centres for tyred wheels for tractive and trailing stock; Quality prescriptions.

ISO 1005-4 Railway rolling stock material – Part 4: Rolled or forged wheel centres for tyred wheels for tractive and trailing stock-Quality requirements.

Features:

- Machining: Wheel center should be full machined according to the product drawing includes hub, rim, web and etc.

- Material: strictly matching the specification.

- Test Certificate: Chemical Analysis, Tensile Test, Dimension and Surface Finish provided according to the specification. NDT- Ultrasonic and Magnetic Inspection could be done per customer request.

- Heat Treatment Delivery Status: U-untreated and N-Normalized or Normalized and Tempered.

CASTING WHEEL CENTRE

However, except the forged wheel center, according to Chinese railway standard, TEDRAIL also could offer customer qualified casting steel wheel center per following specifications:

- TB/T 1400 Techncial specification for cast steel wheel core for railway locomotive

Features:

- Material: ZG230-450, AAR M201 GRADE B, GRADE B+, GRADE C

- Machining: Wheel Center Hub and Rim is machined. Web is left for casting area.

- Test Certificate: Chemical Analysis, Tensile Test, Sectional Checking, Magnetic Particle Inspection, Dimension and Surface Checking.

- Heat Treatment Delivery Status: Normalized or Normalized and Tempered.

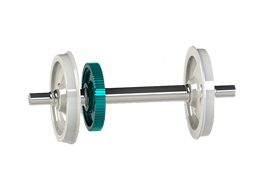

WHEEL TYRE

TEDRAIL Supply the wheel tyre for the tied wheel usage. Wheel tyre has been forged, then hot rolled according to the necessary wheel tyre drawing.

Dimensions could be controlled as:

Rough turned wheel tyre

Finished turned wheel tyre.

DIMENSIONS

TEDRAIL could supply wide dimension range of wheel tyre as following parameters:

| OUTSIDEDIAMETER (MM) | WIDTHOFTREAD (MM) | GAUGE (MM) | MASSWEIGHT (KG) | AXLELOAD (TON) |

| 780-1700 | 120-150 | 1000-1676 | 176-250 | 12-35 |

MANUFACTURING SPECIFICATIONS:

Following Specifications and Tolerance are available by TEDRAIL for customers ordered:

BRITISH STANDARD: BS 5892 PART 4, Railway rolling stock materials –Part 4. Specification for forged and rolled tyres.

EUROPEAN STANDARD: UIC 810-1Technical specification for the supply of rough rolled non-alloy steel tyres for tractive and trailing stock

EUROPEAN STANDARD: UIC 810-2 Technical specification for the supply of rough tyres for tractive and trailing stock - Tolerance

CHINESE RAILWAY STANDARD: TB/T 1882 Technical specification for the supply of rough rolled wheel tyres for railway rolling stock.

CHINESE RAILWAY STANDARD: GB 8602 Rough-Rolled tyres for railway

ISO 1005-1 Railway rolling stock material – Part 1: Rough-Rolled tyres for tractive and trailing stock-Quality requirements.

ISO 1005-2 Railway rolling stock material – Part 2: Tyres, wheel centers and tyred wheels for tractive and trailing stock – Dimensional, balancing and assembly requirements.

ASTM A551 Standard Specification for Carbon Steel Tires for Railway and Rapid Transit Applications

MATERIAL GRADE:

Based on our long term supply experience, TEDRAIL could supply following materials for the wheel tyres

BS 5892-4: GRADE B1N,B2N,B3N,B4N,B5E,B6E,B7E

UIC 810: B1N,B2N,B3N,B4B,B5E,B6E

ASTM A551: Class A, Class AHT, Class B, Class BHT, Class C, Class CHT, Class DHT

TB/T 1882: LG61

GB 8602: LG60,LG65

HEAT TREATMENT DELIVERY STATUS:

Hot Rolled status(U)

Normalizing(N)

Quenching and Tempering(E)

TEST CERTIFICATE

The test result are confirmed in the Certificates 3.1; 3.2 according to the EN 10204 Standard including following testing:

Chemical Analysis

Tensile Test

Impact Test (KU)

Brinell Hardness (uniformity)

Ultrasonic Flaw Detection

Magnetic Particle Inspection

Dimension and Appearance Check

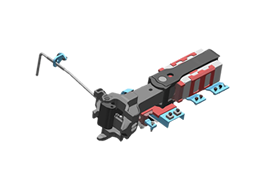

GIBSON RING

Gibson Ring, as well as called retaining ring is arranged between the wheel tyre and wheel center, to prevent the occurrence of relative motion. It has been pressed by Gibson Ring Rolling Machine into the wheel tyre. The Rolling Machine will press the wheel tyre to be deformed and so as to fasten the Gibson Ring.

TEDRAIL can supply the gibson ring according to almost all international standards, such as:

BS 5892-5 Railway Rolling Stock Materials (metric) – Part 5: Specification for steel bars for retaining rings for tyred wheels

UIC 810-3 Technical Specification for the supply of non-alloy flat and sectional steel for tyre retention spring rings.

TEDRAIL has been in producing Gibson ring for following types of A ,B,C,D according to BS5892-5:1987 or UIC 810-3 .We can also customize gibson rings according to customer drawing.

| NO | ITEM NO | PRODUCT TYPE | PRODUCTION METHOD | Materia | SPECIFICATION | COUNTRY |

| 1 | WL0010 | A | Cold drawing | 40B/BS4360 | BS5892-5:1987 | EUROPEAN,IRAN |

| 2 | WL0060 | B | Cold drawing | 40B/BS4360 | BS5892-5:1987 | EUROPEAN,IRAN |

| 3 | WL0061 | C | Cold drawing | 40B/BS4360 | BS5892-5:1987 | EUROPEAN,IRAN |

| 4 | WL0062 | D | Cold drawing | Fe 360B/ISO630 | UIC 810-3 | EUROPEAN,IRAN |