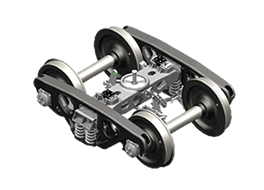

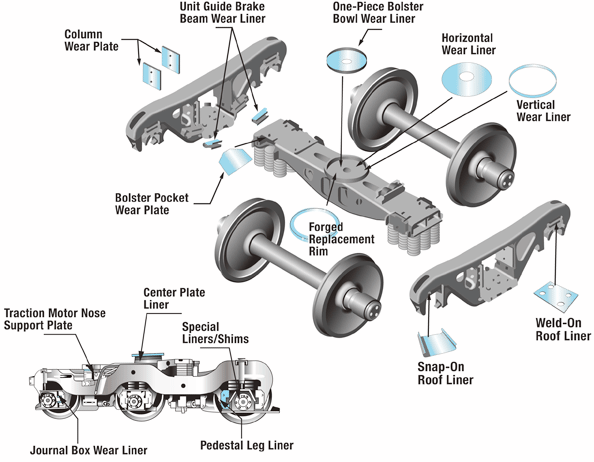

In the railroad industry, friction can be a real problem. While wear on components is inevitable, advances in the design of wear prevention products can significantly impact the overall endurance and operating performance of the rail car. TEDRAIL can provide prompt delivery of freight and transit cars, locomotive truck and coupler wear plates, liners, and shims. We have extensive fabrication capabilities, personal service, and low cost make. In addition to AAR standard wear plate products, we also offer custom specifications for the repair shop. TEDRAIL produces not only high manganese steel fabrications, but also wear parts of carbon, low alloy, stainless, and other corrosion-wear-resistant materials.

TEDRAIL is an innovator in wear prevention and has pioneered solutions that have truly advanced the industry.

Our wearing plate products include:

Bolster Pocket Wear Plate

Column Wear Plate

Unit Guide Brake Beam Wear Liner

One-piece Bolster Bowl Wear Liner

Horizontal Wear Liner

Vertical Wear Liner

Forged Raplacement Rim

Snap-On Roof Liner

Weld-On Roof Liner

Manganese Coupler Carrier Wear Plate

TEDRAIL has already supplied a big amount of wear plate to our long term cooperated customers at the area of United States, South Africa, Indonesia, Malaysia, India, Bangladesh and other countries. Following table is listed on our currently supply range. Of course, TEDRAIL can exactly make the wear plate according to customers’ designed drawing.

| NO | TEDRAIL P/N | PRODUCT DESCRIPTION | WEARING PLATE MATERIAL | WEARING PLATE HARDNESSS/ OTHER TEST | COMMENTS | CUSTOMER AREA |

| 1 | WP0001 | Unit Guide Brake Beam Wear Liner | AISI C-1095 steel | 36-42HRC | Designed to work with any size or manufacture of brake beam Metallic Brake Beam Wear Guide | USA/ CANADA/ MEXICO/ AUSTRALIA |

| 2 | WP0005/ WP0004/ WP0006/ WP0007/ WP0008/ WP0009 | Snap-On Roof Liner | AISI-C1080/1090 STEEL | 39-45HRC | Used for 70T BOGIE,14" Flat, Center Bowl, Black | |

| 3 | WP0010 | Bolster Pocket Wear Plate | ASTM A 514 type B , ASTM A 666 type 304 alloy steel or approved equivalent | Eat treated to 321 min. BHN | All bolster pocket wear plates flat within .025”. | |

| 4 | WP0011 | Column Wear Plate | Hot wrought carbon steel bar | 365-415HBN | CS, 3/8"x7 1/2"x9 7/16", Bolt On, Round Hole | |

| 6 | WP0012 | One-piece Bolster Bowl Wear Liner | XP-91, black copolymer with four grounding contacts. | 12" x 1 1/8 " , 14" x 1 1/8" , 16 "x 2" Bolster bowl must be designed to accept horizontal and vertical wear liners. | ||

| 7 | WP0013 | Horizontal Wear Liner | ASTM A 514 STEEL | Manganese Horizontal Center Bowl Liner. Meets AAR S-305 & S-307 Stds 13.75” and 15.75” Available (3” hole) | ||

| 8 | WP0014 | Vertical Wear Liner | ASTM A240 type 304 or A666 type 304 stainless steel, cold or hot rolled, annealed and pickled. | non-magnetic 128-201 BHN solution anneal (quench anneal) austenitize at 1850°f and water quench. | 14" x 1 1/8", 16 "x 1 3/4", 16 "x 2"Bolster bowl must be designed to accept horizontal and vertical wear liners. | |

| 9 | WP0015 | Forged Replacement Rim | AISI-C1030 STEEL | eat treated to 350min HBN,AND approximate 300BHN AT 1/8"depth | 12" x 1" ,14" x 1 " ,16 "x 1 3/8" Forged rim | |

| 10 | WP0016 | Weld-On Roof Liner | AISI-C1080/1090 STEEL | 39-45HRC | Used for 70T BOGIE,14" Flat, Center Bowl, Black | |

| 11 | WP0017 | Coupler Carrier Wear Plate | ASTM A128 GAR CAST MANGANES STEEL, or heat-treated C-1040/1045 special bar quality steel | Coupler Carrier Wear Plates meet AAR S-26, 11-14% manganese steel, 9/32” or 7/16” THICK AVAILABLE |

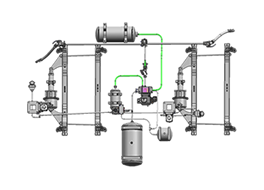

WP0001

Product Description:Unit Guide Brake Beam Wear Liner

Material:AISI C-1095 steel or ASTM A-689 Spring Steel

Hardness:36-42HRC

Size or Spec:AAR S-367 standard or according to client’s drawing

- Tedrail P/N:

WP0001

Product Description:Unit Guide Brake Beam Wear Liner

Material:AISI C-1095 steel or ASTM A-689 Spring Steel

Hardness:36-42HRC

Size or Spec:AAR S-367 standard or according to client’s drawing

WP0001 - Tedrail P/N:

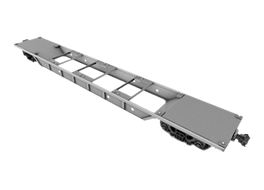

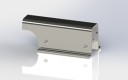

WP0005/WP0004/WP0006/WP0007/WP0008/0009

Product Description:Snap-On Pedestal Roof Wear Liner

Material:AISI C-1080, C-1090 or Equivalent

Hardness:39 ~ 45HRC

Comments:All bolster pocket wear plates flat within .025”.

WP0005/WP0004/WP0006/WP0007/WP0008/0009 - Tedrail P/N:

WP0010

Product Description:Bolster Pocket Wear Plate

Material:AISI-C1080/1090 STEEL

Hardness:36-42HRC

Comments:Used for 70T BOGIE, 14" Flat, Center Bowl, Black

WP0010 - Tedrail P/N:

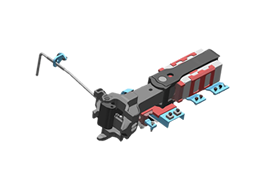

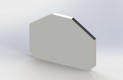

WP0011

Product Description:Column Wear Plate

Material:11 ~ 14% Manganese Steel, Abrasion Resistant Steel, ASTM A514 Steel

Hardness:365-415HBN

Comments:3/8"x7 1/2"x9 7/16", Bolt On, Round Hole

WP0011 - Tedrail P/N:

WP0012

Product Description:One-piece Bolster Bowl Wear Liner

Material:XP-91, black copolymer with four grounding contacts.

Hardness:365-415HBN

Comments:12" x 1 1/8 " ,14" x 1 1/8" ,16 "x 2"Bolster bowl must be designed to accept horizontal and vertical wear liners.

WP0012 - Tedrail P/N:

WP0013

Product Description:Horizontal Wear Liner

Material:11 ~ 14% Manganese Steel, Abrasion Resistant Steel, ASTM A514 Steel

Hardness:365-415HBN

Comments:Bowl Liner meets AAR S-305 & S-307 Standard, 13.75” and 15.75” Available (3” hole)

WP0013 - Tedrail P/N:

WP0014

Product Description:Vertical Wear Liner

Material:Stainless Steel, ASTM A240 type 304 or A666 type 304

Hardness:BHN non-magnetic 128-201 solution anneal (quench anneal), austenitize at 1850°f and water quench.N

Comments:14" x 1 1/8",16 "x 1 3/4",16 "x 2"Bolster bowl must be designed to accept horizontal and vertical wear liners.

WP0014 - Tedrail P/N:

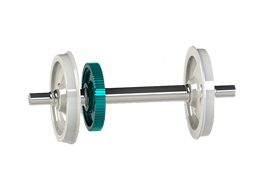

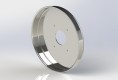

WP0015

Product Description:Forged Replacement Rim

Material:AISI-C1030 STEEL

Hardness:Heat treated to 350min HBN, and approximate 300BHN AT 1/8"depth

Comments:12" x 1", 14" x 1 ", 16 "x 1 3/8" Forged Rim

WP0015 - Tedrail P/N:

WP0016

Product Description:Weld-On Roof Liner

Material:AISI C-1080, C-1090 or Equivalent

Hardness:39 ~ 45HRC

Comments:Used for 70T Bogie, 14" Flat, Center Bowl, Black

WP0016 - Tedrail P/N:

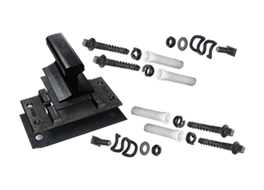

WP0017

Product Description:Coupler Carrier Wear Plate

Material:ASTM A128 Grade Cast Manganese Steel, or heat-treated C-1040/1045 special bar quality steel

Hardness:Heat treated to 350min HBN,AND approximate 300BHN AT 1/8"depth

Comments:Coupler Carrier Wear Plates meet AAR S-26, 11-14% manganese steel, 9/32” or 7/16” THICK AVAILABLE

WP0017